The Customer

Our customer, a prominent player in the Personal Care Industry with a significant market share, operates high-speed label lines for hand washes, body washes, and fragranced products. With a focus on quality and efficiency, they sought solutions to address disruptions caused by snapping label backing paper.

Nature of the Problem

Our customer faced frequent recurring issues with snapping label backing paper, leading to

downtime and operational disruptions. These disruptions prove very costly. They

communicated that downtime costs them £9 for every minute their lines are not running.

Because they supply to large retailers, there can also be large financial penalties for delays

within their supply chain. While die-strike was initially considered, a thorough examination

revealed no evidence of heavy cuts on the backing paper.

Solutions Recommended

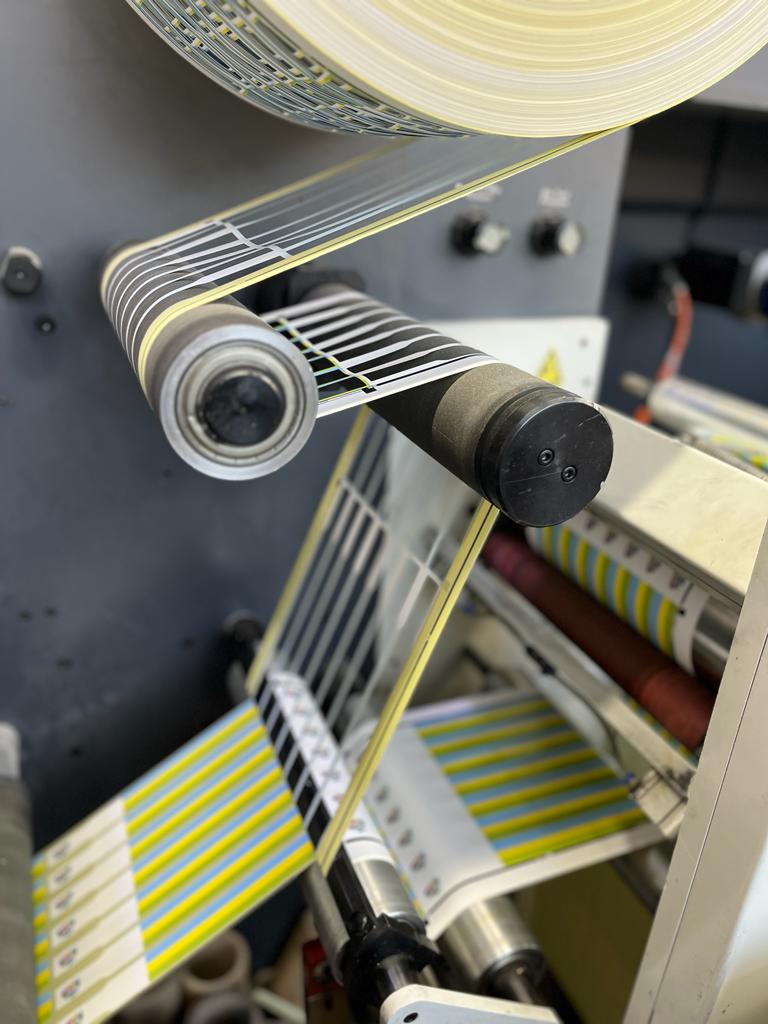

To address the recurring issue of snapping label backing paper, we recommended a transition to PET liners, departing from the standard paper glassine liners. PET liners are renowned for their superior durability and resistance compared to traditional paper glassine liners. By making this transition, the risk of label snapping during high-speed application is significantly reduced, resulting in smoother label application processes and enhanced operational efficiency.

Understanding Backing Papers for Application Lines

In label application lines, the choice of backing paper is paramount to ensure efficiency and performance. PET liners stand out due to their robustness and flexibility, making them ideal for high-speed label application. With PET liners, production processes run smoothly and uninterrupted, contributing to overall operational excellence.

Alternative Solutions

While alternative solutions were explored, including adjustments to machinery settings and adhesive formulations, transitioning to PET liners emerged as the most effective and practical solution. PET liners offered a comprehensive solution to address the root cause of snapping label backing paper.

The Results

Following the transition to PET liners, our customer experienced a significant reduction in label application disruptions. Downtime decreased by 30%, leading to improved production efficiency and cost savings. The materials are marginally more expensive which has been offset by the improvement in efficiency. Customer feedback highlighted the seamless integration of PET liners into their label application process, resulting in enhanced overall performance.

Conclusion

In summary, the implementation of PET liners has yielded positive outcomes for our

customers within the Personal Care Industry. By mitigating label snapping issues, our

solution has contributed to smoother label application processes and improved operational efficiency. This case study underscores the significance of collaboration in finding innovative solutions to address industry-specific challenges.