The Power of Transparent Labels for Bottles

As a discerning consumer, have you ever admired a product’s beauty without realising there’s a label attached? Welcome to the world of clear sticker labels – a clever tool that combines visibility and branding without compromising a product’s aesthetic appeal. Used widely on items such as bottles, perfumes, cosmetics and food, these labels have revolutionised the world of packaging.

Made primarily from materials like clear vinyl, these labels offer the dual benefit of transparency and waterproofing. And with options for custom shapes and text, they’re not just functional, but also a creative canvas for brands. But the magic doesn’t stop there. Ever heard of sandwich printing? It’s a unique technique that makes transparent labels a real eye-catcher.

So, let’s delve deeper into the fascinating world of transparent labels, their uses, benefits, and the innovative techniques that make them a standout choice in product packaging.

Understanding Transparent Labels for Bottles

To understand transparent labels, its really important to know and understand the different materials available

(and their acronyms!)

- Polyethylene (PE): PE labels are known for their flexibility and resistance to water, oil, and chemicals. They are suitable for applications where durability and moisture resistance are important.

- Polypropylene (PP): PP labels offer excellent tear resistance and are often used in applications where labels need to withstand rough handling or outdoor exposure.

- Polyester (PET): PET labels are highly durable and resistant to moisture, chemicals, and extreme temperatures. They are commonly used in industries such as electronics, automotive, and healthcare.

- Polyvinyl Chloride (PVC): PVC labels are durable, flexible, and weather-resistant. They are commonly used for outdoor signage, bumper stickers, and product labels.

- Polyolefin: Polyolefin labels are made from a class of polymers that includes polyethylene and polypropylene. They offer good printability and resistance to water, oil, and chemicals.

- Synthetic Paper: Synthetic paper is a plastic-based material that resembles traditional paper but offers superior durability and water resistance. It is commonly used for applications such as outdoor signage, maps, and product labels.

- Polycarbonate (PC): PC labels are highly durable and resistant to abrasion, chemicals, and extreme temperatures. They are often used for labels on equipment and machinery.

Transparent labels have had a significant evolution, especially for bottle packaging. Made predominantly of PE, these labels offer ease of blending into a bottle’s surface, enhancing a brand presentation without detracting from the bottle design, artwork or its contents.

Another noteworthy detail is the adhesive characteristic – it’s permanent. Once attached, these labels form a secure bond with the bottle, ensuring a long-lasting application. So, no worries about peeling or any issues related to label detachment.

One compelling feature of these labels is their waterproofing. They offer a solid yet transparent shield. Even when subjected to damp environments, they can maintain their integrity and legibility over time, making them an ideal option for beverages or products exposed to moisture.

Transparent labels also offer a solution to colour matching constraints. With their see-through nature, they easily bypass the need to match the label’s colour with the bottle, saving on costs and effort. Brands can sometimes find difficulty in matching their company colour on a product label. Hence, these labels act as a perfect workaround, promoting brand identity without the need for colour matching.

Then there’s the “sandwich printing” technique, adding further charm to transparent labels. This allows a view of the back label through the bottle and its content. For instance, consider a situation where a bird is printed on the back label and a cage on the front. It appears as if the bird is sitting in a cage when seen from the front, creating an imaginative visual experience that boosts a product’s appeal.Finally, we have the “no-label look” labels, giving the impression of printing directly on the bottle. They use crystal-clear film and a clear adhesive that keeps them in place while adapting to curves and irregularities. This technique ensures absolute transparency, removing visible adhesives, and providing the impression of a completely label-free look, yet with all necessary information intact.

Material Options for Transparent Labels

Delving further into the nature of transparent labels, it’s essential to consider the materials available. Predominantly, the transparent labels are made from PE or PP. These durable materials lend themselves well to being printed on and also adhere securely to many surfaces.

Another material of choice is vinyl. Transparent thanks to its inherent characteristics, vinyl offers the ability to see through the labels. It’s a well-known choice for labels that require robust waterproofing features. Bottles are often exposed to moisture, condensation, or in contact with water during use, making vinyl a logical material choice.

Many may also prefer PET (Polyethylene terephthalate) for transparent labels. Prized for its clarity, chemical resistance, and excellent stability, PET serves perfectly as a material for labels that must maintain integrity under testing conditions, for example, freezer foods, drinks, and outdoor products.

Flexibility and adaptability to various shapes are critical when choosing material for transparent labels. It’s not just about standard shapes like square, round, rectangle, and oval. Customisation plays a significant part. If a particular text needs printing on the label then custom shapes become crucial. From unique die-cut options to traditional forms, the desired shape can be achieved with the correct material and clear label printing options.

Moreover, some labels feature a special gloss finish. This glossy sheen can draw attention to the label. It proves especially useful if the label is sticking onto a surface that itself has a gloss finish. For instance, a wine bottle. The matching gloss finish of the label and the bottle surface creates a cohesive aesthetic that can help engage the customer’s attention.

The waterproof nature of certain materials also serves a functional purpose. Transparent labels often need to cover existing print on a bottle, enabling new information to overlay without obfuscating the text beneath. In such a scenario, waterproofing capabilities are crucial to ensure the legibility of both layers of print.

The material choice for transparent labels is guided by the need for clarity, adherence, waterproofing capabilities, and potential customer engagement. Making the right choice can significantly impact the effectiveness of the label and, by extension, the product’s perception.

Designing Your Clear Bottle Labels

Positioning transparent labels effectively forms the cornerstone of creating remarkable product packaging. These labels offer a level of flexibility seldom seen, coupled with avoiding the extra cost of traditional screen printing methods. Specifically, these ingenious labelling methods allow for intriguing effects, like enabling a view into the bottle.

Bolster the appeal and value of your ‘no-label look’ labels. Achieve this by tactically combining the transparent film with exotic colours, eye-catching shapes, and luxurious hot foils. The ‘no-label’ look serves as a testament to the apex of design and quality printing in the realm of labels. The labels curated in this way ensure a robust and clear presentation at the point of sale.

Transparent labels sporting the ‘no-label’ look are seen commonly across industry corridors. Popular sectors leveraging this unique labelling style include the cosmetics, food, and beverage industries that swear by these labels’ visual appeal and quality. Irrespective of the industry your business operates in, the ‘no-label’ look concept is universally applicable.

Labelling is crucial in branding your products, merchandise, or packaging. Therefore, choosing a professional label provider makes all the difference in product presentation. In conclusion, transparent labels offer flexibility, low entry-level costs, and the ability to incorporate interesting effects. Furthermore, by combining transparent films with special colours, shapes, and hot foils, you can significantly increase the aesthetic appeal of your brand. Remember, high-quality labels enhance product perception, influencing purchase choices.

Efficacy of Transparent Labels in Various Sectors

A remarkable success story, transparent labels have made strides in various sectors, notably in cosmetics, beverages, and food packaging. Take vanity products, for example. Custom clear labels enhance the visual aesthetic, showcasing individuality with a luxurious feeI.

Exploring beverages, particularly wines and craft beers, we’ve noticed a similar label love affair. Elegantly designed transparent labels offer a peek into the beverage’s colour – an enticing aspect for potential buyers. They help foster a mystical bond between the product and customer, presenting an illusion of the content and label in perfect synergy.

In the food industry, transparent labels aren’t just about charm; they serve a practical purpose. They provide consumers with a glimpse of what’s inside the packaging: the colour, texture, and freshness – critical aspects when food shopping. There’s a certain comfort in transparency that enables decision-making.

Yet, the best representation of these labels perhaps stems from sandwich printing that creates captivating visuals. Imagine a bottle with a front and back label, both transparent, with printing on the inside. From the front, it appears as though a picture is floating within the bottle — a surrealistic mirage brought to life by transparency.

Then there’s the ‘no-label’ look. This technique effectively masks the label with the packaging by exploiting the adaptability of transparent polypropylene film and clear adhesive. It provides an illusion of direct-on-product printing that exudes a high-quality feel.

The efficacy of transparent labels spans aesthetics to practicality, panache to comfort. It’s a strategy that, when employed right, can revolutionise a brand’s visual presence. But remember, these effects rely heavily on the choice of film, adhesive and the label’s application, so it pays to find an experienced label provider.

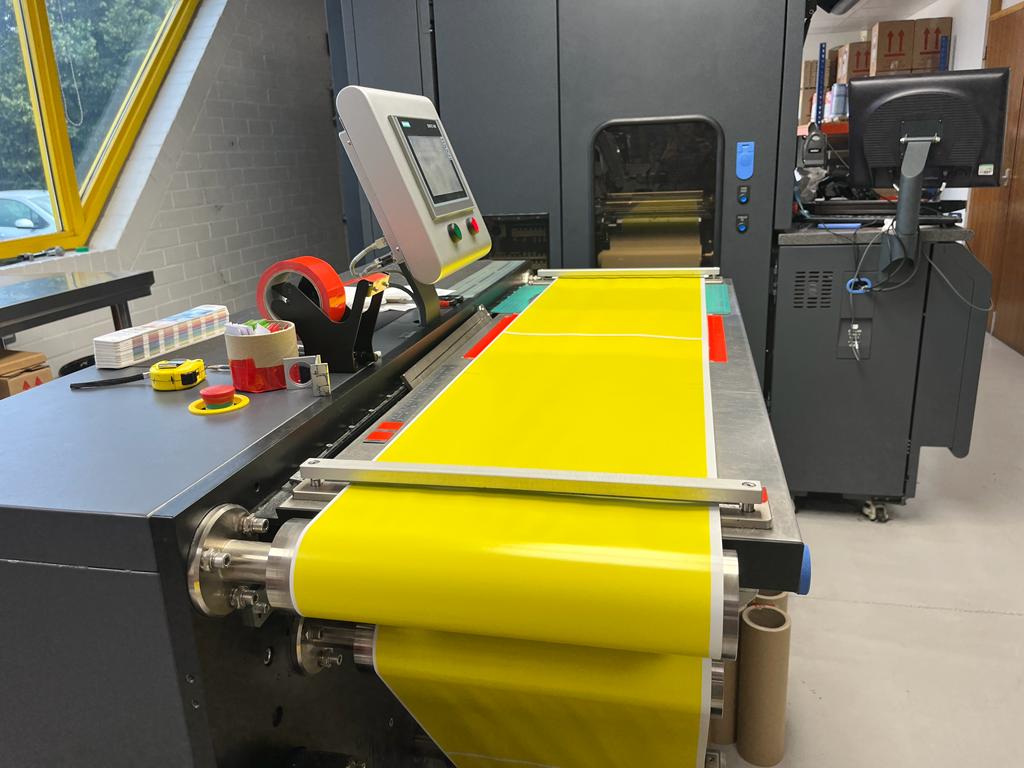

Technical Aspects of Transparent Label Printing

Stepping in a more technical direction, we need to explore the material and adhesive attributes. The labels are constructed predominantly using PP and PE. This durable material retains its transparency, doesn’t distort or fade over time, and it’s waterproof..

The adhesive is permanent and its invisible nature is integral to maintaining a ‘no-label look’. As observed, it sticks well, doesn’t dilute the transparency, and is lasting, yet flexible to adapt to the product’s surface, be it curved or irregular. However, it’s also recommended to apply these labels using a machine. Doing so prevents air inclusions and structure formations of the adhesive, major deterrents to attaining the perfect ‘no-label’ look.

Let’s delve into the properties that make transparent labels stand out; their high-quality visuals and diverse design freedom. The secret lies in the printing process on a crystal-clear film. These films essentially create an illusion of direct printing on the product packaging. Their key attribute is the resistance to elements, flexibility in adaptation, and most important, the clear portrayal of the labels.

However, it’s worth mentioning a major limitation. The ‘no-label look’ gets compromised with the application of finishes like protective varnish or foil lamination, be it matte or glossy. These finishes tend to make the labels lose their transparent clarity and create an undesired milky look.

In short, the technical aspects of transparent labels encompass the material, adhesive, printing process, finishes, and innovative techniques. Each element plays a pivotal role in creating labels that are not only strikingly beautiful but also truly practical.

Conclusion

We’ve taken you through the world of transparent labels for bottles, highlighting the undeniable benefits they offer. From their evolution to the modern-day innovations, it’s clear that these labels are more than just a packaging solution. They’re an integral part of your brand’s story, influencing consumer perceptions with their visual appeal. With the right material, printing technique and adhesive, you’re guaranteed a label that’s not just attractive but durable and waterproof. Remember, the print quality of your label reflects the quality of your product. So, whether you’re a small business owner or a major player in the industry, investing in high–quality transparent labels is a smart move. It’s all about making that first impression count, and with transparent labels, you’re sure to make a lasting one. Why not contact our design service team to find out how we can help?

Transparent Labels for Bottles FAQs

- Premium ‘no label’ look: Film materials can provide a high-quality, label-free appearance, which is often desirable in craft beer, spirits, and personal care products.

- Flexibility and conformability: Film labels can easily conform to curved or irregular surfaces, making them suitable for containers with unique shapes.

- Weather and moisture resistance: Films, particularly polyester, offer excellent resistance to weather conditions and moisture, ensuring that the label remains intact and legible even in challenging environments.

- Tear resistance: Films are generally more durable and resistant to tearing compared to paper labels.

- UV, heat, chemical, and abrasion resistance: Polyester film, in particular, exhibits extreme durability and can withstand exposure to UV rays, high temperatures, chemicals, and abrasion.