Digital Label and Sticker Printing

As one of the first UK label manufacturers to invest in digital technology, Anglia Labels has been at the forefront of digital printing for over twenty years. We are proud to be key players in what is still the biggest growing sector in the label printing industry.

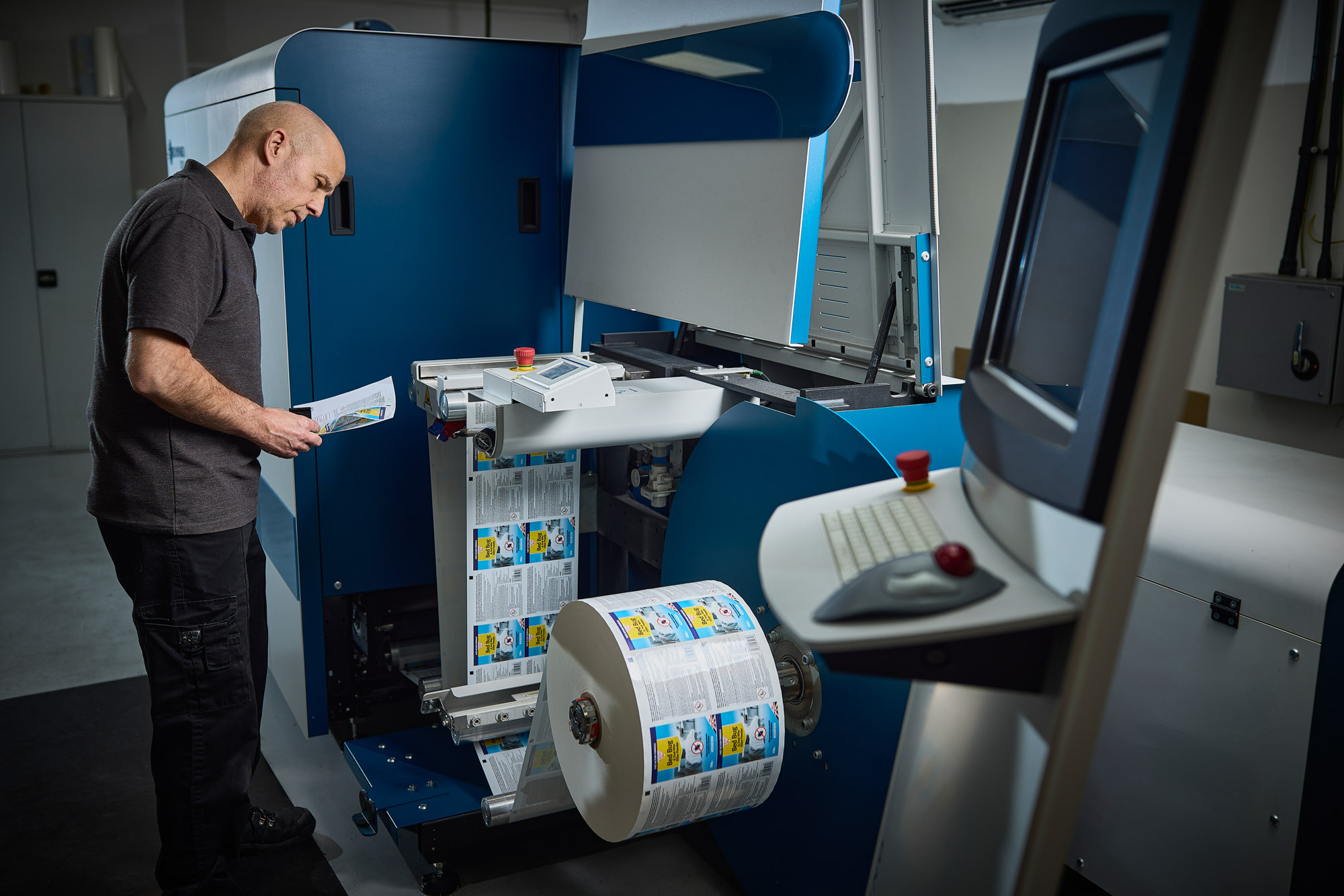

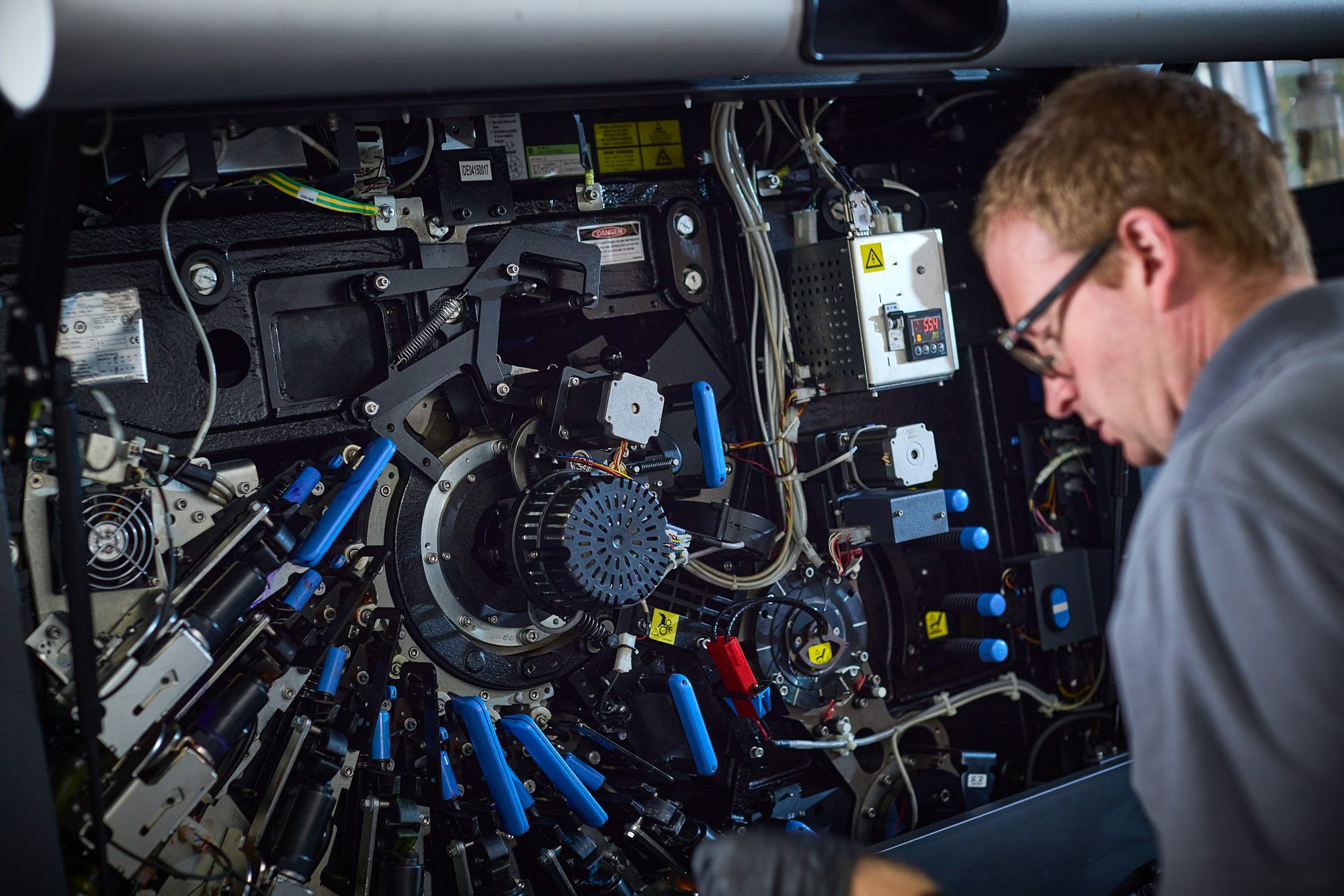

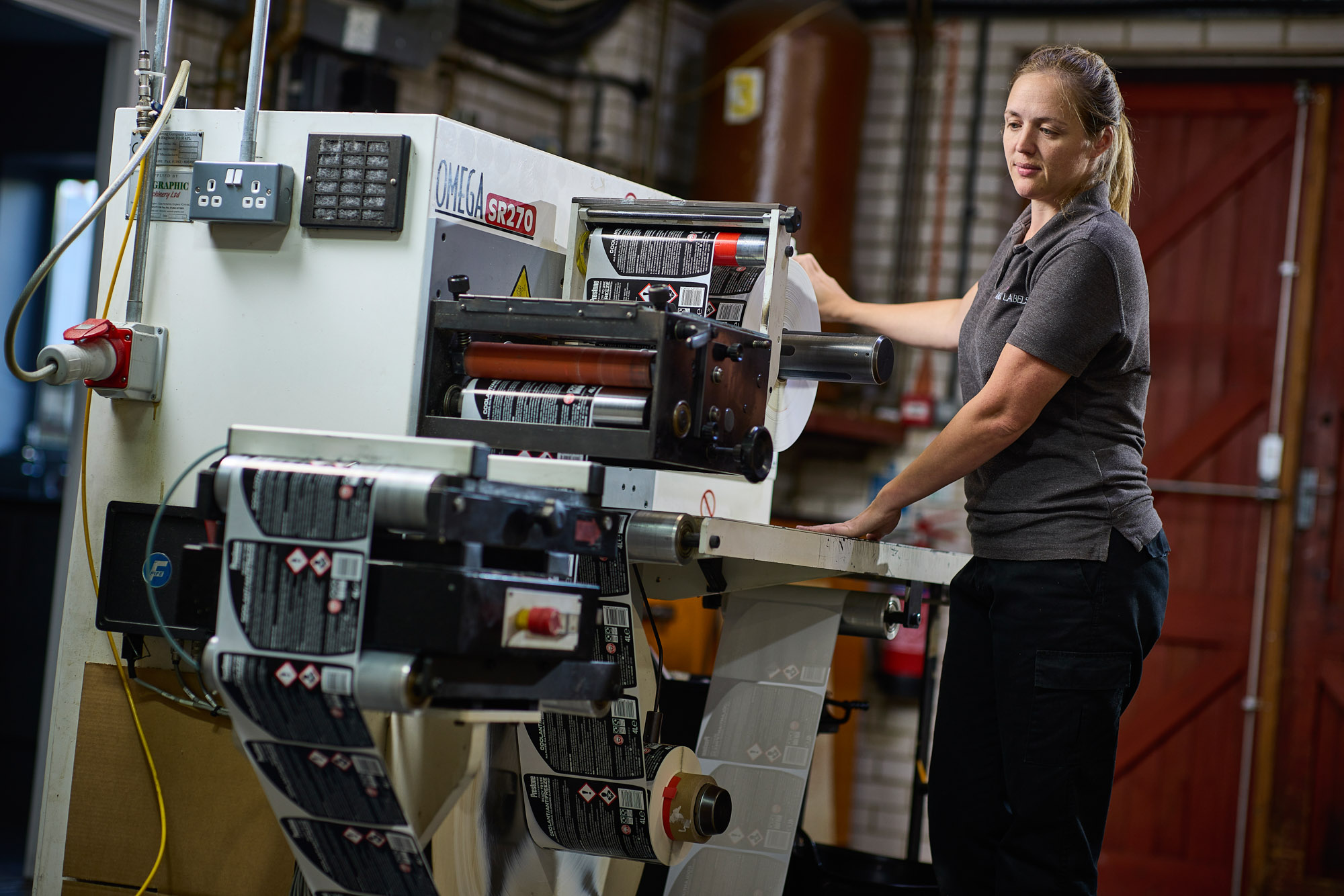

Digital printing offers many benefits and with our impressive combination of HP Indigo and Domino machines, we offer a wide range of innovative label solutions.

Digital label printing for quality, flexibility,

and advanced finishing

Cost-effective

With no ink mixing, colour matching or plate costs, digital printing is cost-effective and delivers excellent quality at high speeds.

Shorter runs & multiple sorts

Digital printing is a perfectly flexible solution for short to medium-run lengths over multiple variants. It allows for on-demand printing and a range of variable data options including personalisation, sequential barcodes and numbering.

Quality colour & durability

With a light fastness of 8 on the wool scale and the highest opacity of opaque white, our presses offer further scope to create enhanced digital imaging. Accurate colour matching using a seven-colour pallet and perfect registration guarantees a quality result. With anti-abrasion and UV-resistant inks, the quality and colour will be long-lasting.

Advanced Finishing

Using our state-of-the-art DACO finishing units digital print can be finished with a variety of spot or overall varnishes. The print can also have an over laminate, a hologram or foil added to create the complete finished label. The finished print can be supplied on reels, fan-folded or on sheets.

Contact us for expert support from start to finish

Anglia Labels can help with the design and customisation to help you achieve your desired result. Contact us and our team of technical experts to discuss your label needs.

Take your labels to the next level with digital print

Take your labels to the next level with digital print – Digital label printing offers a range of benefits over traditional printing processes. With digital presses, we provide custom digital labels at the UK’s lowest prices. When you choose digitally printed labels, you can customise the size, shape, and design of your labels and stickers. This printing technology allows quick turnaround times for short-run sticker printing, perfect for brand promotions or limited edition products.

Using digital allows for full-colour print quality with the option to add metallic or UV finishes for a premium look. Say goodbye to expensive printing plates and lengthy setup times with flexographic printing. Our digital label printing service also includes UK delivery, making it easy and convenient to get your labels and packaging printed. Whether you need a one-off print run or a regular supply of custom-size labels, digital print is the way to go.

Applications of digitally printed labels

Digitally printed labels offer a wide range of applications across various industries. With the latest digital printing technology, companies can now produce high-quality stickers and labels in a much more efficient manner. The main benefit of digital label printing is the ability to have custom-printed labels with a quick turnaround time, often within a few working days. These labels can be made waterproof, have a variety of finishes and textures, and are also sustainable as a packaging solution.

From product labels for food and drink items to window stickers for signage, digitally printed labels cater to a huge range of needs. Companies can now bespoke their labels with the exact design and specifications they want without worrying about minimum order quantities. The flexible packaging and greater flexibility than traditional label production make digital printing a popular choice in the industry.